Yeah, that’s pretty aggravating.

💡 Pro tip: You can also refer to these dents and holes as fish eyes in resin. I like how calling it a fish eye somehow makes it sound more exotic and unplanned. But not as much fun as these fish eyes you can read.

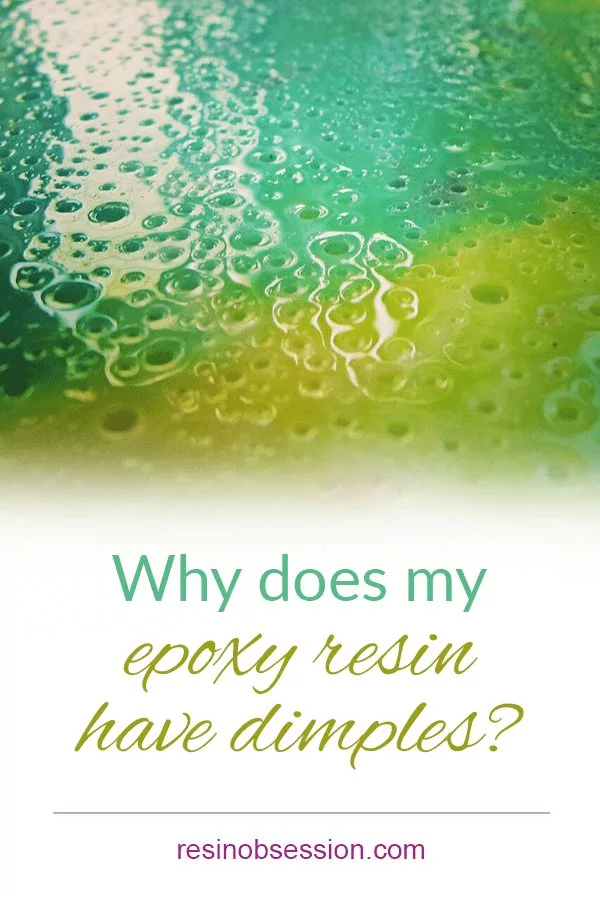

Here are a few explanations about why you may have dimples on your epoxy surface:

1. You didn’t use the right resin.

When pouring resin to coat a surface, it must mix thick enough so that it wants to stay on the surface. Not all resins want to do this. Resins meant for casting, mix thin, and won’t self-level. If you want the best epoxy resin to coat a surface, you need to choose one specifically for that job. That means you want to use a doming resin for your project.

💡 Pro tip: If this is new to you, learn more here: What’s the difference between doming resin and casting resin?

Resin Obsession has two doming resins that work great for coatings:

If you want an excellent quality artwork resin at an affordable price, then check out the Resin Obsession artwork resin. It takes colors well, or you can leave it clear.

If you want a coating resin with our best UV protection, then you will love the Resin Obsession crystal doming resin. It’s great for small jewelry projects and coating tumblers.

2. You didn’t use enough resin.

Even if you use the right epoxy resin for your project, if you don’t use enough of it, it’s not going to cover your surface evenly. It will pull away in places and create dimples. Doming resins are formulated to self-level to a depth of one-eighth of an inch. You need to be sure you mix enough resin to cover your surface length and width to an eighth of an inch deep.

Now before you go all crazy thinking you need to do math, here’s where you can hit the easy button. Use the Resin Obsession resin calculator. It calculates the amount of resin you need to coat a surface or fill a mold, making sure you don’t waste precious resin or get dimples in your epoxy.

💡 Pro tip: Mix a smidge more than the calculator tells you. Why? Speaking from experience, I find I always need a little extra. I like to have enough to make more of a resin color I’m already pouring or mix a little for a new color.

And if you do have a little extra, you can use it to make this leftover resin ring.

3. Something is repelling the resin from your surface.

While resin mixes with a lot of things, oil isn’t one of them. While adding liquids like silicone oil or hair serum can create cells in resin, it can also cause dimples in epoxy.

If you are making an epoxy tumbler, you need to make sure the surface is clean before coating it with resin. Wash with a good-quality soap and water or wipe with isopropyl alcohol first if possible. Oily surfaces also include wax and tape adhesives, so make sure those are off of your resin surface as well.

4. Your surface has dents and valleys that the resin can’t completely fill.

A doming resin only self-levels to 1/8 inch deep. Even if you use enough resin, the resin isn’t going to rise up taller than that without a little help. This is where using painter’s tape or masking tape to create a dam around your project is essential to get the resin to layer deeper.

💡 Pro tip: Since doming resins are meant to pour in a thin layer, pouring them deeper can mean more bubbles. You will want to use a heat gun to get rid of those resin bubbles.

5. You manipulated the resin towards the end of the pot time.

I get it. It’s tempting to continue to work on your masterpiece as long as you can. But, there is a ‘point of no return’ where working the resin won’t let it self-level. When you work with it right as the pot time is running out, you will get dimples in your epoxy that won’t go away before curing.

So what do you do if this happens to you? I’m so glad you asked!

Here’s how you fix dents and holes in your resin painting.

Tired of making resin mistakes?

Good. I’ve made them all for you! 😜 Instead, learn from my sixteen years of resin experience to fast-track your success. It starts with getting a copy of my ebook, Resin Fundamentals. For less than the price of a resin kit, you can buy the downloadable PDF that shows up in your email inbox in minutes.

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

Will mold release cause this too? I am creating pendants in tiny narrow tubes (prisms and cylinders), and I have to use a tiny paint brush to get mold release into the silicone pendant tube molds. I leave it overnight to dry, but I still get holes and divits in the pendants. I’m so unhappy. I can’t get them out without mold release, but I wonder if it’s causing the problem too.

Hi Arielle, mold release won’t cause this in your pendants. It sounds like you are trapping bubbles on the mold surface. This article will give you some ideas on things you can try differently: https://resinobsession.com/resin-frequently-asked-questions/resin-bubbles/

Thanks this was very helpful for my table where I applied artwork resin and got bumps. I suspect I manipulated the resin towards the end of the pot time. How can I tell what is the “end of pot time”? I didn’t see any instructions on the containers about how quickly I must use up the resin (note, after I stir for about 3 minutes, I have used a tip I found at this website to let it sit for about 7 minutes to let the bubbles evaporate), so I’m about 10 minute in before I start to pour. One time I worked with resin it got obviously hot and hard towards the end so it was clear I should stop pouring, but are there other ways to tell if I’ve used it too long, before I get to the hot/hard point? Thanks

Hi Tricia, if it’s a resin we sell, we include that information in a PDF you can download on this page: https://resinobsession.com/resin-frequently-asked-questions/resin-casting/. Otherwise, you will need to contact the manufacturer for that detail.

Hi, I keep getting some sort of dry residue that sits on top of my resin every time , it’s driving me nuts & costing me a fortune, every time I sand & re coat n the same thing happens , please help.

Hi Alisha, I’ve never heard of anything like this. Have you reached out to the manufacturer for help?

Hi I have a problem when I cast objects in my silicone molds. After they cure there are circular holes or missing resin from several sides of the finished project. What am I doing wrong and can I put the pieces back in the molds and pour a little resin just in the areas where the resin is missing?

Hi Stanley, it sounds like you are trapping bubbles in your mold. Unfortunately, putting it back in the mold and adding resin doesn’t work very well.

Stanley I had the same issue. I now put my poured molds into a pressure pot which forces the resin into all the crevices.

Hi, this was helpful but my fisheyes are still tacky, how can I correct this problem? I used an epoxy resin, can I sand everything & use a doming resin? Can I sand if spots are still tacky?

Hi Karissa, I’m sorry to hear your resin is tacky. This article explains how to fix it: https://resinobsession.com/resin-frequently-asked-questions/how-to-fix-sticky-resin/

Hi thank you so much for all the information you have provided for us! I do have a question which I can’t seem to find an answer to anywhere. I’m currently making trays and using Mica powders. I’m noticing that the resin around the mold is pulling upwards towards the center of the mold and the middle of the resin is stationary. Its creating a frame like image . It’s hard to explain but does that sound like a normal reaction?

Hi Adriana, this is normal as the resin heats up.

Hello

I am trying to epoxy a thermos and tumbler I spray painted. It always ends up with big fisheyes. I feel I use enough epoxy to cover for I have some left over and it drips off. Could the spray paint have the oil in it you talk about, and should I soap and water it before I epoxy it. I have stripped them and started over so many times I want to pull hairs out. Help please, if you can.

Thanks

My resin finish has small divets Ive used a lot of resin and less resin, 3 different brands of tiles used a lot of a torch n less, cleaned tiles well and it still does it. I am not a beginner help its costing me an arm and a leg

Hi Mary, I’m sorry this is so frustrating for you. I offer coaching calls for situations like this. You can get the details here: https://resinobsession.com/contact-us/

I keep getting tiny fish eye divots after the resin has cured and I’ve removed it from the mold. At this point, what can be done to fix them?

Hi Angela, I’m sorry this is happening to you. This article will give you some ideas: https://resinobsession.com/resin-frequently-asked-questions/how-to-fix-dimples-in-epoxy-resin/

Hi I’m wanting to coat my wooden wedding ring with epoxy resin to help protect the wood and metal used as it has started to scratch . Is it possible to apply epoxy resin to the external side of my wedding ring and what’s the best way to do this

Hi, I am 12 years old and a beginner. I don’t really know what I’m doing yet. I just received some resin supplies, and I made my first project 15 minutes ago. I looked up what the best tempo for resin curing was, and it said not under 75 degrees. So I searched up if I can put it in the oven. Can I put it in right after pouring? The web doesn’t say much.

Hi Addie, do you have an adult helping you with this? Resin crafting isn’t something I recommend for someone you’re age.

Hi Katherine- This is Addie’s mom. Me and her Dad are around if she needs anything:) But she’s just doing little projects and having a great time learning as she goes! Thanks for your input!

Hi Addie’s mom, thanks for chiming in. I’m glad to hear she’s got adult help while she’s learning resin.

To help speed up curing, this article will help: https://resinobsession.com/resin-frequently-asked-questions/how-to-make-resin-dry-faster/

Not really. I’ve searched for videos of all the problems I could think of could happen, and I’m trying to figure it out on my own and just see what happens. Thank you for your time!