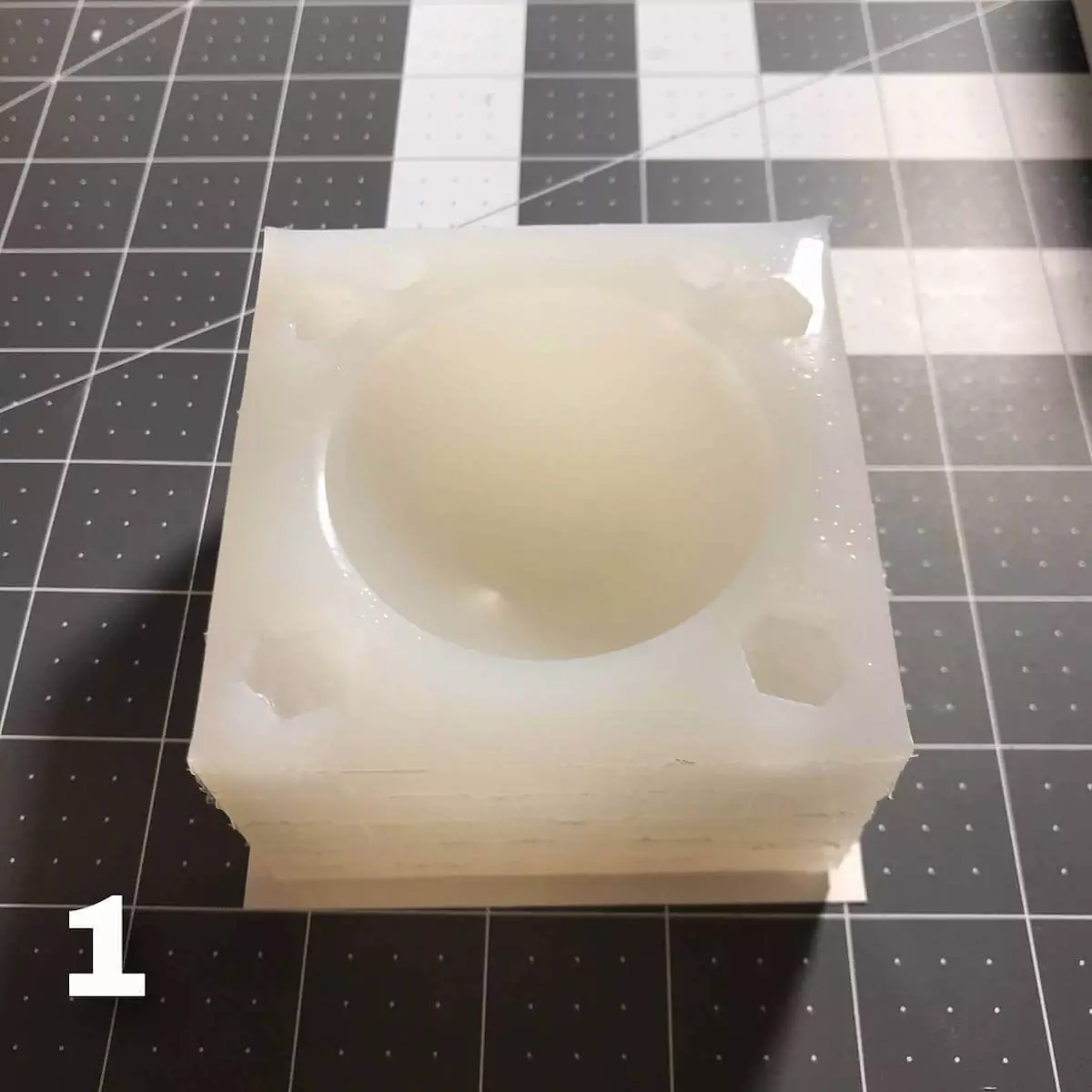

These are two-part sphere molds I make myself.

I heat whichever resin type I’m working with in a water bath. I want to get the resin to about 77-80 degrees F when I’m ready to pour.

After I pour the first base layer into my silicone mold, I cover it with a container. This seals any dust from entering and retains the heat as the exothermic reaction occurs.

After I add the second layer, I cover the mold again to let it cure. But before I cover it, I activate a HotHandsTM hand warmer about 15 minutes before the final epoxy pour so it gets up to max temperature, which is super important in cold weather. Then, I place it next to the mold and cover it with a container.

I put some weight on top to help retain heat and prevent dust from getting into the resin.

This technique has not only improved the quality of the castings but has also dramatically cut down the cure time.

I’m a night owl, so I generally cast late. Before using the warmer during curing, if I returned about 12 hours later, the resin would still be sticky and not ready to handle. Using the HotHands and sealing the mold from the 55-60 degree working temperature in my garage during the winter months, all of my castings have come out perfect and cured FAR quicker.

I’ve been casting for a while now. Moving forward, this will be my method when my garage is under 70 degrees F. I’ve used this process with fourteen different epoxy, polyester, and polyurethane resins and gotten better results every time.

This shows how my epoxy castings came out in cold weather before using the heat pad. It’s a night and day difference!

Struggling to get the results you want with resin?

Download your copy of Resin Fundamentals. The ebook, written with over a decade of practical resin experience, will take you from confused to confident with resin in an afternoon. Buy now and get an email download link in minutes.

Originally written Jason Bell of Ballistic Impressions

Unpublished Blog Posts of Resin Obsession, LLC © 2023 Resin Obsession, LLC

Mmm I am having a very hard time this winter! Our house is seldom more than 68 degrees and very little I do can get it warmer (eastern WA, drafty windows.) The only resin I can get to cure bubble-free is easycast epoxy, and then only if I mix it in hot water and cure it on a heating pad. The nicer ones I’ve bought are 100% useless rn. I wish someone would come up w a good cool-weather resin!

Hi Sarah, wouldn’t that be nice! I’m afraid though, that resin really does best in the low 70’s F for curing. Have you tried making a resin hotbox? That might work for what you want to do. I show how to do it in this article: https://resinobsession.com/resin-resin-resin/casting-resin-in-cold-temperatures/

In my experience, it’s all about retaining the heat from the exothermic heat reaction. As Katherine said, a hot box of sorts is an easy solution. For most of my pieces, I just use an external heat source and seal the mold with a plastic container. The heat mat is a creative way to do this as well. I just purchased one off Amazon last week, along with a thermostat to control the temperature. Once I run out these heat pads I have on hand, I’ll try out that method. I like the idea of being about to control the heat temperature and duration each piece is exposed to that heat. Happy casting! Jason

Sigh, yes. I might try the hotbox, though I might just scale down production until summer. (My family would thank me for that anyway!)

Unfortunately, that may be what you have to do. 🙁

Wow amazing difference!

I preheat the resin also. I coat my 18x 24″ works of art. I use a space heater and make a tent with my tarp. I turn the space heater toward the tarp, away from the resin, to prevent the fan of the space heater from rippling the surface.

I have warmed the two products in hot water for about 20 and tested the temp of the water, before mixing. I wonder if using a heating pad on the surface under the pour would work?

Yes, that will work well.

I’m curing them on heating pads, yep. I also warm the resin up in hot water first. Still, the only one I can get all (okay most of!) the bubbles out of is easycast. The others I have are the resin obsession brand, which I really like if I’m not trying to do something clear, and the jewelry grade one sold on here (forget the brand.) That one has kind of been a disaster. I mix very carefully, but sometimes it cures hard, and sometimes it never gets beyond the goo stage, and it *always* has tons of bubbles. Abandoning that one till summer!

Oh and I actually bought a heat lamp yesterday to try to warm the area up more. The guy that sold it to me was like, “Are you trying to blow yourself up?” XD

Oh goodness. Be safe!

Hi

After reading this great tip I made a wooden box out of MDF lined it with silver foil which I place over my resin project. Under the project I have a reptile aquarium heating mat bought really cheaply on line and it works a treat. I use the warm water bath to mix my resins to begin with.

Thanks Martin

I have an oil filled heater which I used to heat up the room if needed. I can also put the resin on top of the heater on a metal pan while mixing

Seems to work well

Will add a covering after reading the comments

Hi. I want to be sure to get the right product. I would like to pour on a 24″ by 24″ surface of wood which has been rub-coated with tung oil (which will dry to a hard and fairly slick finish). The wood surface is not completely flat; it varies only slightly, not more than 1/32nd inch. I want to end with not more than a 1/8th inch thickness of the resin and I’m looking for a glass-like finish from the resin. So, my questions are: Which product is best for this technique and thickness? Will the resin cure being that thin (about 1/16in. to 1/8in.) without heating (I can move the workpiece inside to about 71 deg. Fahr.)? Is there a surface preparation (such as light sanding) that I must use beforehand to insure a good bond? Many kind thanks for your response. Gray

Hi Gray, resin doesn’t like sticking to oily surfaces. I’m not sure tung oil is going to work. Have you considered a polyurethane finish? Resin will stick to that much better. After coating the surface and letting it dry for at least 30 days, this is the epoxy resin you want to use: https://shop.resinobsession.com/collections/resin/resin-obsession-artwork-resin